Analysis of internal factors affecting the service life of cone crusher - cost reduction

E-mail: jacker@cfcmining.com

As an important industrial production equipment, cone crusher is mainly used for primary processing and crushing of various ores and other raw materials.

Cone crusher has many advantages, such as high breakage efficiency, low energy consumption and good crushing effect. It meets the environmental protection requirements of "more crushing and less grinding" and "lower energy consumption" as well as the technological requirements of "selective crushing". At present, it is widely used in industrial production.

1. Main influencing factors of economic performance of cone crusher

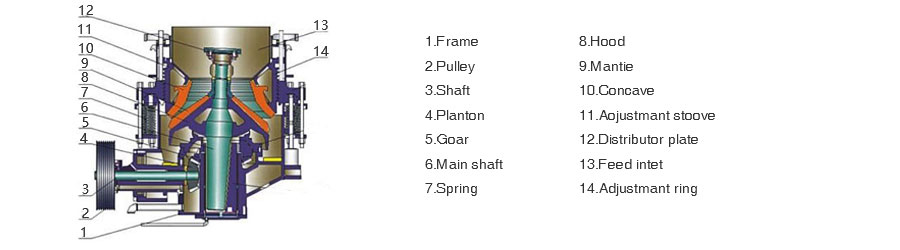

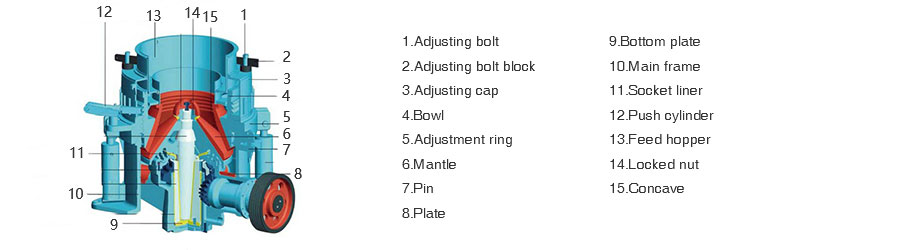

The cone crusher is a very complex crushing equipment, and there are many factors that affect its working performance, including design structure and unreasonable operation in use. According to the structure and working principle of the cone crusher, the main factors that affect the economic performance of the cone crusher in the design structure are put forward. There are mainly three aspects as follows:

The crushing chamber of the cone crusher is the space for crushing between the moving cone and the fixed cone. The cavity shape of the cone crusher is the fundamental factor that affects the performance indexes of the cone crusher, such as production efficiency, energy consumption, crushing degree, etc. Therefore, a reasonable cavity shape design is an important guarantee for the working performance of the cone crusher.

The working parameters of cone crusher are the main factors that affect the working performance of crusher. Whether the working parameter design of the crusher is reasonable or not is directly reflected in the impact of the spindle rotation speed of the crusher in the crushing chamber on the motion law of the crushed materials, and finally reflects the working efficiency of the cone crusher.

1.3 the influence of the rotating moving distance of the cone crusher's crushing chamber on the working performance of the crusher

The rotating distance of the cone crusher is also an important factor affecting the working performance of the crusher. When the rotating distance of the cone crusher increases, the crushing compression ratio in the crushing chamber is directly increased, the quality of the crushed products is improved, and the working performance is improved; otherwise, when the rotating distance of the cone crusher decreases, the crushing compression ratio in the crushing chamber is directly reduced, the quality of the crushed products is reduced, and the working performance of the cone crusher is reduced.

2.1. Inspection and treatment method of clearance between main shaft and taper sleeve

In the daily maintenance of the clearance between the taper sleeve and the main shaft, only the upper clearance is detected, that is, a section of fuse with moderate thickness is pasted at the upper opening of the taper sleeve with thin edge and thick edge respectively. Lift the cone and the main shaft into the cone hole. The cone sphere shall be compacted on the bowl tile. Then lift out the cone and measure the thickness of the two fuses. The value is the measured clearance between the upper opening of the cone sleeve and the main shaft. The adjustment of the clearance between the main shaft and the taper sleeve can be realized by changing the thickness of the sizing block on the contact surface of the bowl bearing seat and the frame. When measuring the backlash of large and small bevel gears, the heavy edge of eccentric sleeve should be on the side of small bevel gear.

When the contact range is less than one quarter of the taper sleeve height, or the contact point within the area of 50mm × 50mm is less than one point, the three edge scraper or angle grinder shall be used to scrape and grind the high point of the inner hole. Meanwhile, the steel ruler shall be used to detect the bus bar of the inner hole at the grinding position, and the visual clearance measurement shall be zero, and the rough grinding shall meet the requirements. Apply abrasives on the contact surface, put the cone into idle running for 10 minutes, lift it out for inspection and grinding, and operate repeatedly until the contact range is more than one quarter of the height of the cone sleeve, and contact with the main shaft evenly, and the contact point within the area of 50mm × 50mm is more than one point; when a crack with the length less than 200mm appears on the upper opening of the cone sleeve, along the direction of the bus, but it does not affect the contact between the cone sleeve and the main shaft In case of clearance, a crack stop hole with a diameter of 8-10 mm can be drilled at the lower end of the crack to continue to be used; when the thin side of the eccentric shaft sleeve bulges inward due to heat, the inner hole shall be polished with a grinder, and the edge of the steel ruler shall be tested along the bus direction of the taper hole. Insert the taper sleeve and run it in the taper hole, and polish and check it repeatedly according to the matching condition. The clearance between the taper sleeve and the eccentric sleeve hole shall be less than 0.1mm.

After the abrasives are evenly applied on the spherical surface of the moving cone, the moving cone body and the bowl shaped tile are mutually grinded, so that the contact points are evenly distributed in the 1 / 3-1 / 2 ring of the radius of the bowl shaped tile, the wedge-shaped clearance of the inner circumference is kept between 0.5-lmm, not less than one contact point in every 25 mm × 25 mm area, and there is no contact point in the 1 / 2 inner circle of the radius of the other side. In addition, when the wear of the bowl bearing is large, the cone will drop greatly, and the dynamic cone sphere cannot contact with the inner circle of the bowl bearing, so the bowl bearing should be renewed in time.

2.4 treatment method for disc wear of eccentric shaft sleeve

When the wear of the disc on the eccentric shaft sleeve is large, the repair method of surfacing before turning can be adopted; when the wear is small, the other side of the disc can be drilled, and the surface can be adjusted before continuing to use.

2.5. Set up automatic lubrication monitoring system

The lubrication system shall be electrically interlocked with the main motor and the matched feeder to ensure that all driving parts can be fully lubricated during the operation of the crusher. The main motor can be started and operated only after the oil pump is started. When the oil pump stops or the oil pressure is lower than 0.05Mpa and the temperature is higher than 55 ℃, the control system will send a signal, and the main motor and feeder will stop running to ensure that the transmission parts are not damaged. The selection of machine oil can refer to the change of climate. Generally, 40 × machine oil can be used for temperature, 50 × machine oil in summer, 20 × or 30 × machine oil in winter.