what is the difference a cone crusher machine with other rock machine?

E-mail: jacker@cfcmining.com

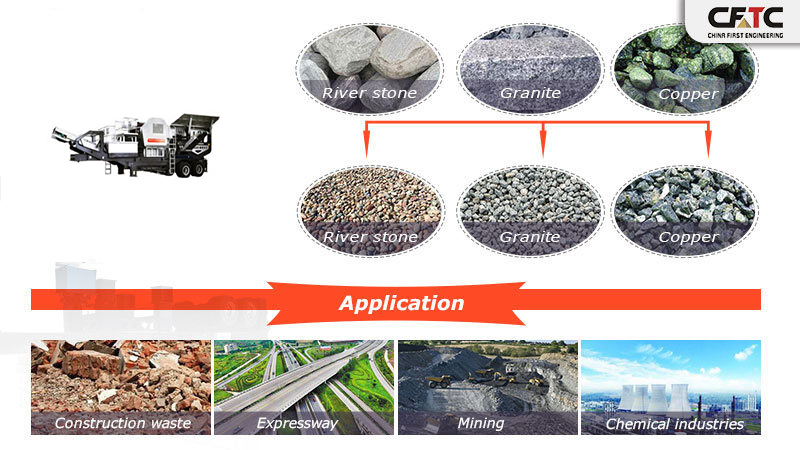

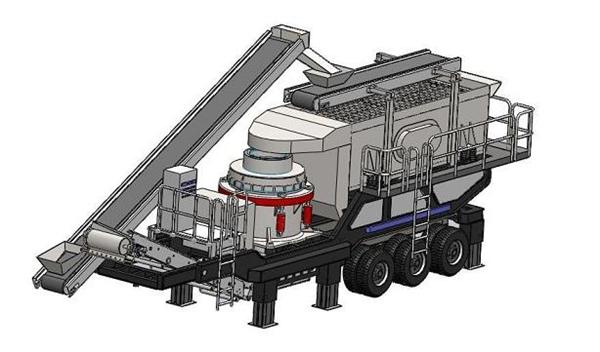

As the star product in the mobile crushing series, the cone crusher has shown a solid quality guarantee in a large number of construction site application conditions.

The cone crusher is a hydraulic cone crusher with high power, large crush ratio, high productivity and high reliability. Cone crushing mainframe is widely used in medium and fine crushing of high hardness materials, especially suitable for ultra-fine crushing hard rock, ore, slag, refractory materials, etc. It is the strength of the crushing equipment!

The cone crushing machine adopts the squeeze crushing principle, and the crushing cavity of the material in the moving cone liner and the fixed cone liner is broken. The moving cone is driven by the large gear and the pinion on the eccentric shaft. The eccentric shaft makes the moving cone swing when rotating, and the material is continuously crushed and crushed between the moving cone linings. The other crushing process is in the material. Produced in mutual friction. Has the following characteristics:

Large crush ratio

Can handle almost all materials (breakable Mo type hardness up to 7)

High number of revolutions

5 speed adjustable

Vibration type, multi-point breakage

Automatic over-iron overload system

Realize the loading without stopping, hydraulically adjust the discharge opening

One-button calibration of wear values, automatic wear value recording, wear indication, and liner replacement instructions

Two production modes: automatic mode (ensure grain size) and maximum mode (ensure production)

Automatic heating, automatic cooling

Flow alarm, low temperature alarm

High temperature automatic shutdown

Bearing transmission: The world's most advanced bearing transmission cone is the biggest highlight of the cone crusher. Compared with the traditional copper-clad cone on the market, the bearing-type cone-changing sliding friction is rolling friction, which reduces the energy consumption and reduces the failure rate of the equipment, while the bearing has higher elasticity in harder applications. And it is not easy to malfunction under high load conditions, which is the biggest guarantee to ensure stable and reliable production of cone crushing mainframe.

Thanks to the bearing transmission, the cone crusher has a variable speed function. The user can use the intelligent electronic control system equipped with the cone main unit to adjust the speed to obtain the required specifications. Compared with the conventional fixed speed cone main unit, the user can It is easy to operate.

Equipped with advanced hydraulic setting system, hydraulic over-voltage overload protection system and reset system. Simple consumable replacement design minimizes downtime. Cone crushers, if used properly, are relatively inexpensive to operate and maintain relative to counterattacks and produce less powder. The crushing process is continuous, and the cone crushing host product has a relatively good grain size.